Compact and High-Performance Monoblock Machines are the Best Solutions for Bottle Cleaning, Liquid Filling and Capping . Find out why!

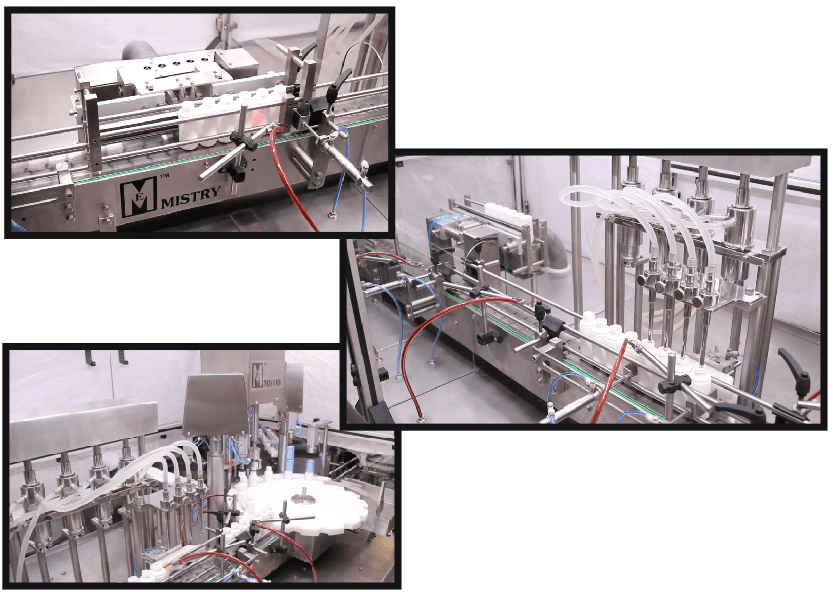

Monoblock Machines are ideal systems for Airjet & vacuum Cleaning, Liquid Filling and Capping bottles made from Glass, HDPE or PET. These Machines are designed to simplify and accelerate bottling operations for companies that need to fill medium to large quantities of bottles per hour. These machines can be customized with different Cleaning, Filling and Capping systems. Therefore, by offering three functions in one, these Machines are capable of providing truly unique advantages with respect to other types of filling systems.

What are the advantages of Monoblock Machines?

For one, Monoblock Machines are compact: this allows the client to optimize their available space.

Being Compact, it gives an added advantage of saving on Manpower. Single Operator can Operate & Control the Entire Process

For example, this Machine is equipped with 6 Station Cleaning, 4 Head Servo Controlled Piston type Syringe Filling & Single Head Servo Torque Capping with Pneumatic Cap Grippers and is capable for providing 2400 Bottles per hour.

Similar Monoblock Machine can also be designed for Filling Viscous Liquids, Gels, Powders, etc.

Optional Features:

- Flameproof with ATEX Certified Components

- 21 CFR Part 11 Compliance

- CE Certification

Are you interested in a Monoblock Machine? Contact us!