Automatic Liquid Bottle Filling Line

Automatic Linear Bottle Washing Machine

Salient Features

- Three types of water washes such as Recycled Water Wash, Purified Water Wash & WFI followed by Sterile Compressed Air

- Pressure transmitter showing Actual Air & Water Pressure on HMI

- HMI with 3 Level Password Access System

Optional

- Industrial Panel PC & SCADA based 21 CFR Part 11 Compliance

| cGMP Model | ME-BW-120 | ME-BW-240 |

|---|---|---|

| Output Speed | Up to 120 Bottles/min | Up to 240 Bottles/min |

| Number of Wash Cycle | Internal: 2 Water + 3 Air External: 2 Water + 1 Air | Internal: 2 Water + 3 Air External: 2 Water + 1 Air |

| Bottle Size | 10mL to 250mL | 10mL to 250mL |

| Machine Dimensions ( L x W x H) | 3000mm x 1200mm x 1400mm | 3000mm x 1500mm x 1400mm |

Automatic Airjet & Vacuum Bottle Cleaning Machine

Salient Features

- Machine fitted with Inbuilt Turn Table (30" Dia) & Bottle Loading Platform for easy Bottle feeding.

- Inbuilt Blower Type Vacuum Generator

- 6-8 Air Cleaning Cycles inside Vacuum Chamber

- Cleaning in Inverted Bottle Neck Down Position for Efficient Cleaning

- HMI with 3 Level Password Access System

Optional

- Industrial Panel PC & SCADA based 21 CFR Part 11 Compliance

- Ionizer Unit for Removal of Static Charges from PET / HDPE Bottles

- Aluminum Section Polycarbonate / Toughened Glass Cabinet

| Model | ME-AJC-80 | ME-AJC-120 | ME-AJC-180 |

|---|---|---|---|

| Output Speed | Up to 80 Bottles/min | Up to 120 Bottles/min | Up to 240 Bottles/min |

| Bottle Size | 10mL to 250mL | 10mL to 500/1000mL | 10mL to 500/1000mL |

| Machine Dimensions with Inbuilt Turn Table ( L x W x H) | 2000mm x 600mm x 1400mm | 2200mm x 600mm x 1400mm | 3000mm x 1000mm x 1400mm |

Automatic Rotary Bottle Washing Machine

Salient Features

- Three types of water washes such as Recycled Water Wash, Purified Water Wash & WFI followed by Sterile Compressed Air

- Servo based Nozzle Motion

- Pressure transmitter showing Actual Air & Water Pressure on HMI

- HMI with 3 Level Password Access System

- No Bottle - No Wash System

Optional

- Industrial Panel PC & SCADA based 21 CFR Part 11 Compliance

| cGMP Model | ME-RBW-120 | ME-RBW-240 |

|---|---|---|

| Output Speed | Up to 120 Bottles/min | Up to 240 Bottles/min |

| Number of Wash Cycle | Internal: 3 Water + 3 Air External: 2 Water + 1 Air | Internal: 3 Water + 3 Air External: 2 Water + 1 Air |

| Bottle Size | 10mL to 250mL | 10mL to 250mL |

| Machine Dimensions ( L x W x H) | 3000mm x 2100mm x 1500mm | 3000mm x 2500mm x 1500mm |

Automatic Linear Bottle Filling Machine

Salient Features

- All Product Contact Parts made form S.S.316

- Volumetric type S.S.316 Syringes

- Servo Controlled Syringes

- Fill Volume Setting from Touchscreen

- Servo based Nozzle Motion

- Recipe Management System for Easy & Quick Changeovers

- Pressure transmitter showing Actual Air & Water Pressure on HMI

- HMI with 3 Level Password Access System

- No Bottle - No Fill System

Optional

- Industrial Panel PC & SCADA based 21 CFR Part 11 Compliance

- Pre & Post Nitrogen Purging

| cGMP Model | ME-LF-60 | ME-LF-120 | ME-LF-150 | ME-LF-180 |

|---|---|---|---|---|

| Output Speed | Up to 60 Bottles/min | Up to 120 Bottles/min | Up to 150 Bottles/min | Up to 180 Bottles/min |

| Number of Filling Heads | 4 Head | 8 Head | 10 Head | 12 Head |

| Bottle Size | 10mL to 1000mL | 10mL to 1000mL | 10mL to 1000mL | 10mL to 1000mL |

| Machine Dimensions ( L x W x H) | 2000mm x 2100mm x 1500mm | 2200mm x 2500mm x 1500mm | 2500mm x 2500mm x 1500mm | 3000mm x 2500mm x 1500mm |

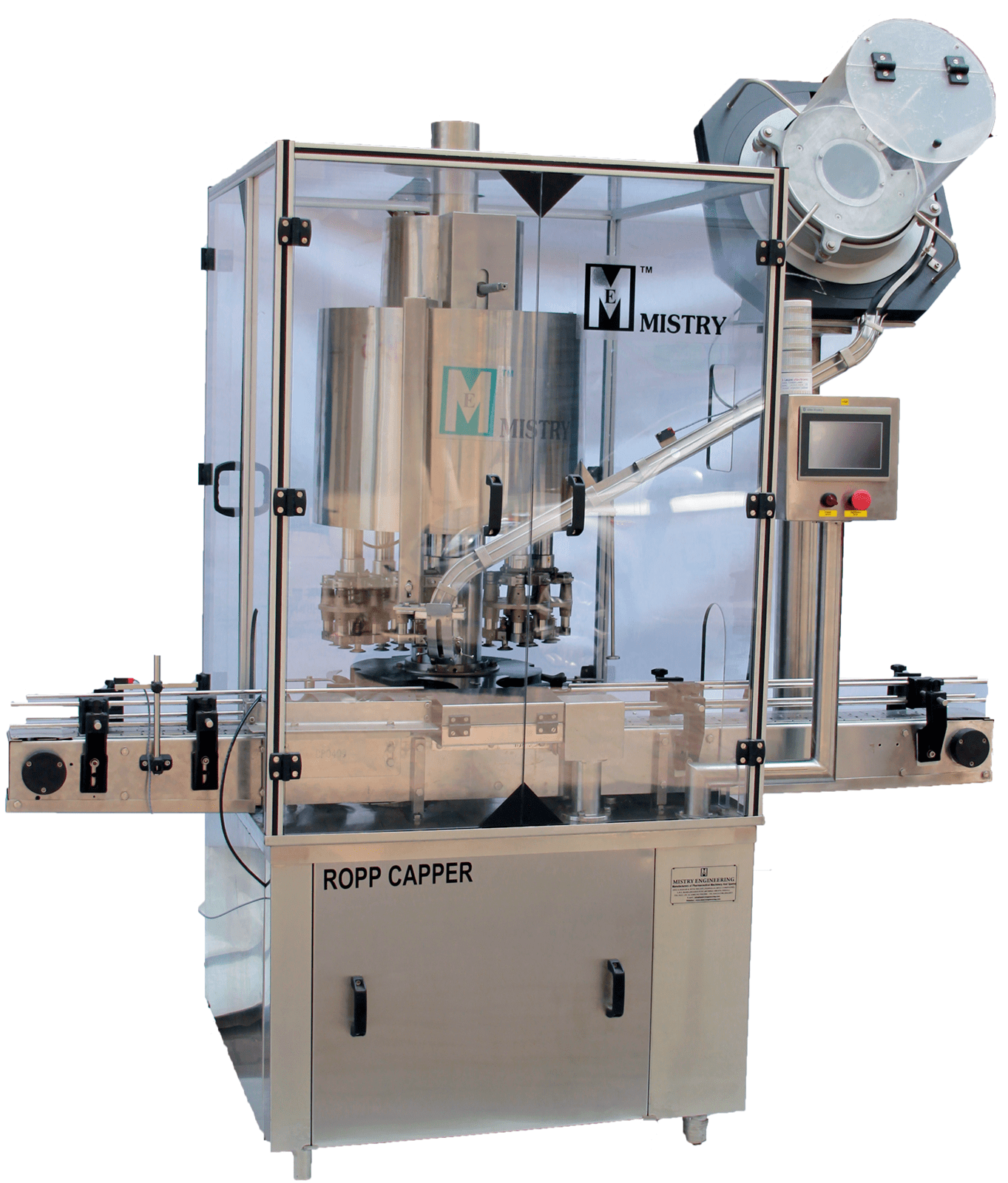

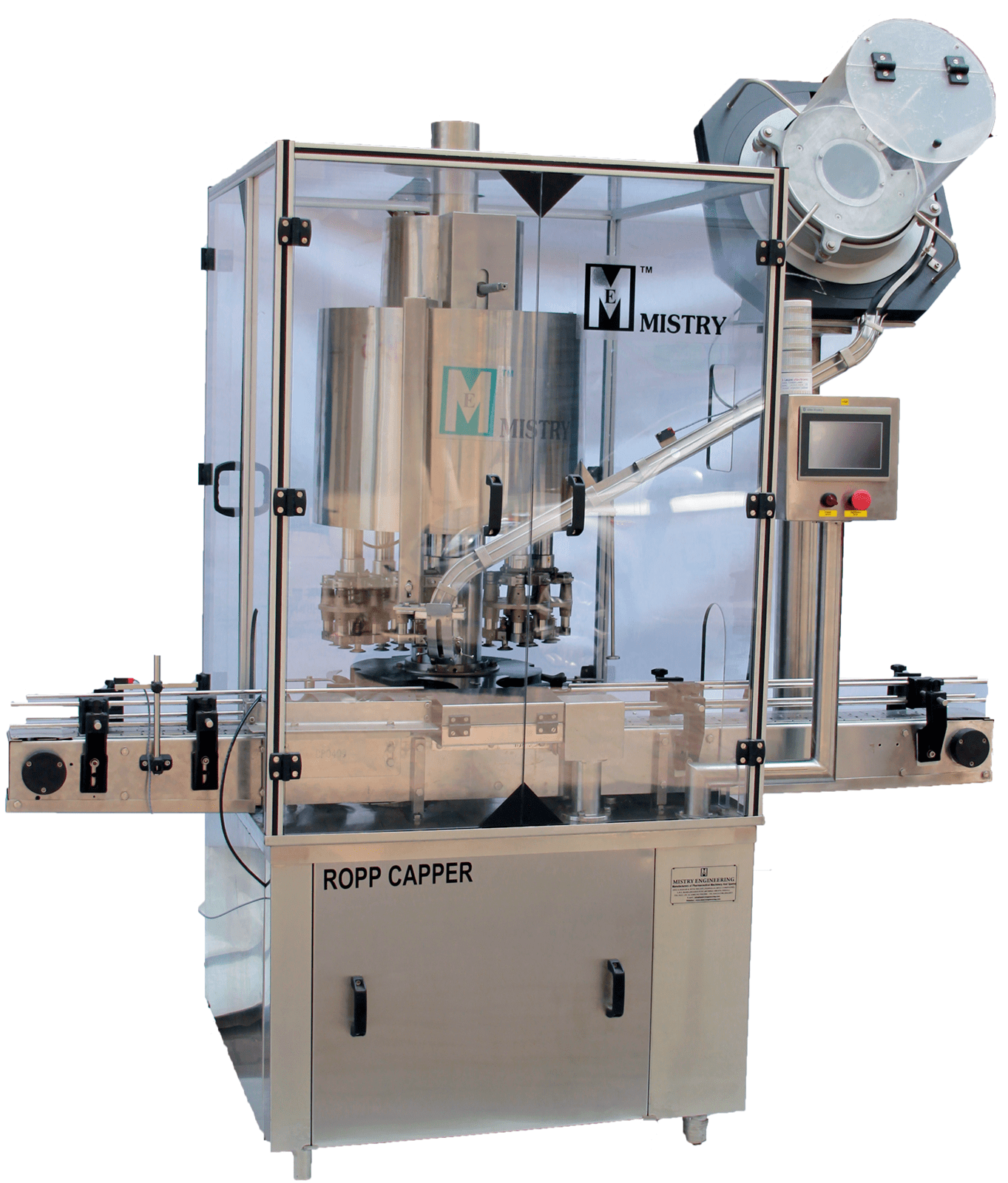

Automatic Multi Head ROPP Capping Machine

Salient Features

- Orientor type Cap Feeder (common for 22mm , 25mm & 28mm ROPP Caps)

- Completely Synchronized Operation of Machine with Conveyor, Starwheel & Centre Turret

- HMI with 3 Level Password Access System

- No Bottle - No Cap Interlock

- Cap Empty in Chute - Machine Stop

Optional

- Industrial Panel PC & SCADA based 21 CFR Part 11 Compliance

- Aluminum Section Polycarbonate or Toughened Glass Cabinet

| cGMP Model | ME-CS-60 | ME-CS-120 | ME-CS-150 | ME-CS-180 |

|---|---|---|---|---|

| Output Speed | Up to 60 Bottles/min | Up to 120 Bottles/min | Up to 150 Bottles/min | Up to 180 Bottles/min |

| Number of Capping Heads | 4 Head | 6 Head | 8 Head | 12 Head |

| Bottle Size | 10mL to 450mL | 10mL to 450mL | 10mL to 450mL | 10mL to 450mL |

| Machine Dimensions ( L x W x H) | 1800mm x 950mm x 1500mm | 1800mm x 950mm x 1500mm | 2000mm x 950mm x 1500mm | 2200mm x 1100mm x 1500mm |

Automatic Multi Head Screw Capping Machine

Salient Features

- Vibratory Bowl type Cap Feeder for Screw Caps

- Pick n Place type Rotary Capping Heads

- Machine suitable for Child Resistant Caps (CRC)

- Manually adjustable Capping Torque Heads

- Completely Synchronized Operation of Machine with Conveyor, Starwheel & Centre Turret

- HMI with 3 Level Password Access System

- No Bottle - No Cap Interlock

- Cap Empty in Chute - Machine Stop

Optional

- Industrial Panel PC & SCADA based 21 CFR Part 11 Compliance

| cGMP Model | ME-SC-60 | ME-SC-80 | ME-SC-100 | ME-SC-120 |

|---|---|---|---|---|

| Output Speed | Up to 60 Bottles/min | Up to 80 Bottles/min | Up to 100 Bottles/min | Up to 120 Bottles/min |

| Number of Capping Heads | 4 Head | 6 Head | 8 Head | 12 Head |

| Bottle Size | 10mL to 450mL | 10mL to 450mL | 10mL to 450mL | 10mL to 450mL |

| Machine Dimensions ( L x W x H) | 1800mm x 950mm x 1500mm | 1800mm x 950mm x 1500mm | 2000mm x 950mm x 1500mm | 2200mm x 1100mm x 1500mm |

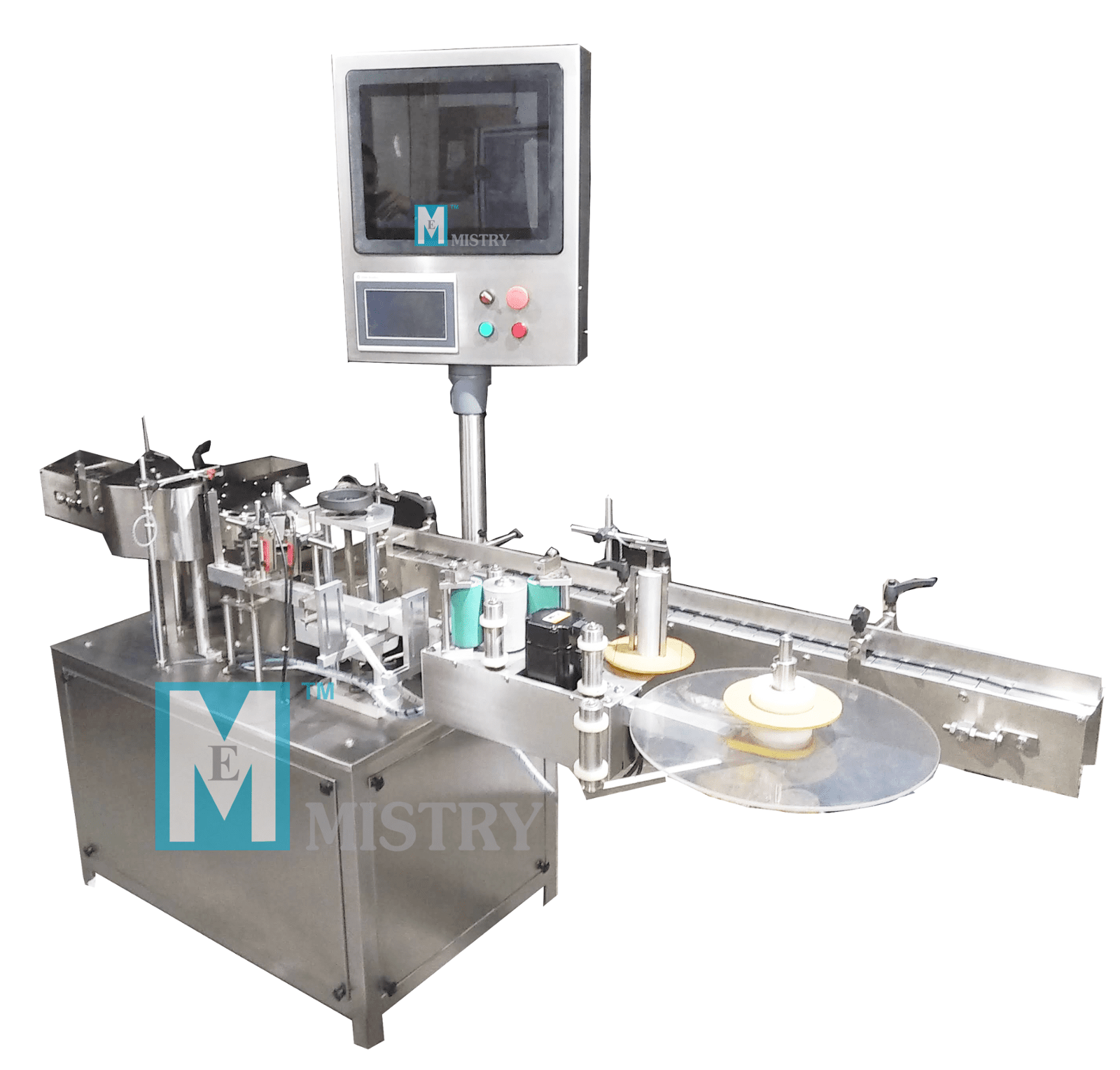

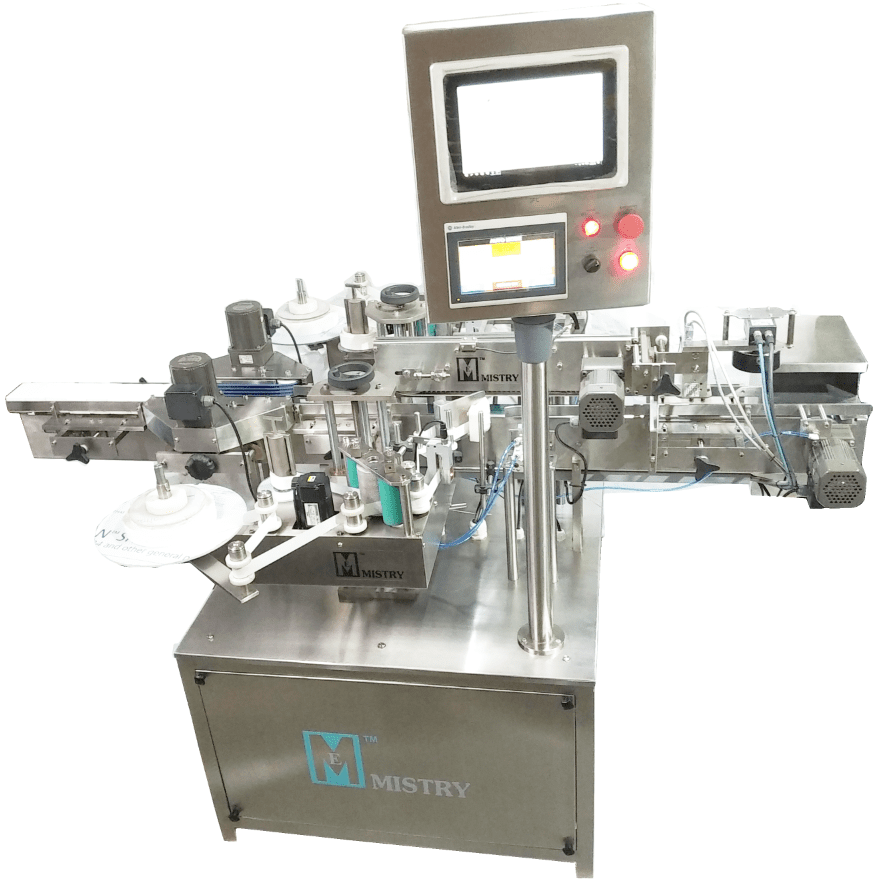

Automatic Sticker Labelling Machine (Round Bottles)

Salient Features

- Completely Synchronized with Individual Drive for Conveyor, Pressing Belt & Infeed

- PLC based Operation

- Servo based Label Dispensing Head

- HMI with 3 Level Password Access System

- Recipe Management for Easy & Fast Changeovers

- No Bottle - No Label Interlocks

Optional

- Industrial Panel PC & SCADA based 21 CFR Part 11 Compliance

- Batch Coding Printer- TIJ (Thermal Ink Jet) or TTO (Thermal Transfer Overprinter)

- Vision Camera based Inspection System with OCR/OCV, 1D & 2D Barcode Checking with Automatic Online Rejection System

- Bottle without Label - Online Rejection & Label Roll Splice Detection

| Model | ME-SL-120 | ME-RSL-240 | ME-RSL-300 |

|---|---|---|---|

| Output Speed | Up to 120 Bottles/min | Up to 240 Bottles/min | Up to 300 Bottles/min |

| Labelling Principle | Linear | Rotary | Rotary |

| Bottle Size | 10mL to 450mL | 10mL to 450mL | 10mL to 450mL |

| Machine Dimensions ( L x W x H) | 2000mm x 700mm x 1500mm | 2500mm x 800mm x 1500mm | 2500mm x 800mm x 1500mm |

Automatic Sticker Labelling Machine (Flat Bottles)

Salient Features

- Completely Synchronized with Individual Drive for Bottom Conveyor, Top Conveyor & Infeed Belts / Worm Drive

- PLC based Operation

- Servo based Label Dispensing Head

- HMI with 3 Level Password Access System

- Recipe Management for Easy & Fast Changeovers

- No Bottle - No Label Interlocks

Optional

- Industrial Panel PC & SCADA based 21 CFR Part 11 Compliance

- Batch Coding Printer- TIJ (Thermal Ink Jet) or TTO (Thermal Transfer Overprinter)

- Attachment for Wrap around Labelling Round, Square & Rectangular Bottles in same Machine

- Vision Camera based Inspection System with OCR/OCV, 1D & 2D Barcode Checking with Automatic Online Rejection System

- Bottle without Label - Online Rejection & Label Roll Splice Detection

| Model | ME-SL-120S | ME-SL-120D | ME-SL-240D |

|---|---|---|---|

| Output Speed | Up to 120 Bottles/min | Up to 120 Bottles/min | Up to 240 Bottles/min |

| Labelling type | Single Side | Double Side | Double Side |

| Infeed Drive | Infeed Belt Drive | Infeed Belt Drive | Infeed Worm Drive |

| Bottle Size | 30mL to 1000mL | 30mL to 1000mL | 30mL to 1000mL |

| Machine Dimensions ( L x W x H) | 2000mm x 700mm x 1500mm | 2500mm x 800mm x 1500mm | 2500mm x 800mm x 1500mm |